Zone

- Australia

- Chile

- France

- Italy

- Mexico

- New Zealand

- Peru

- South Africa

- Spain and Portugal

- United States and Canada

- Africa

- Asia

- Europe

- Latin America

Language

- French

- Spanish

- English

- Services

- About us

- Research & Development

- Careers

- Contact us

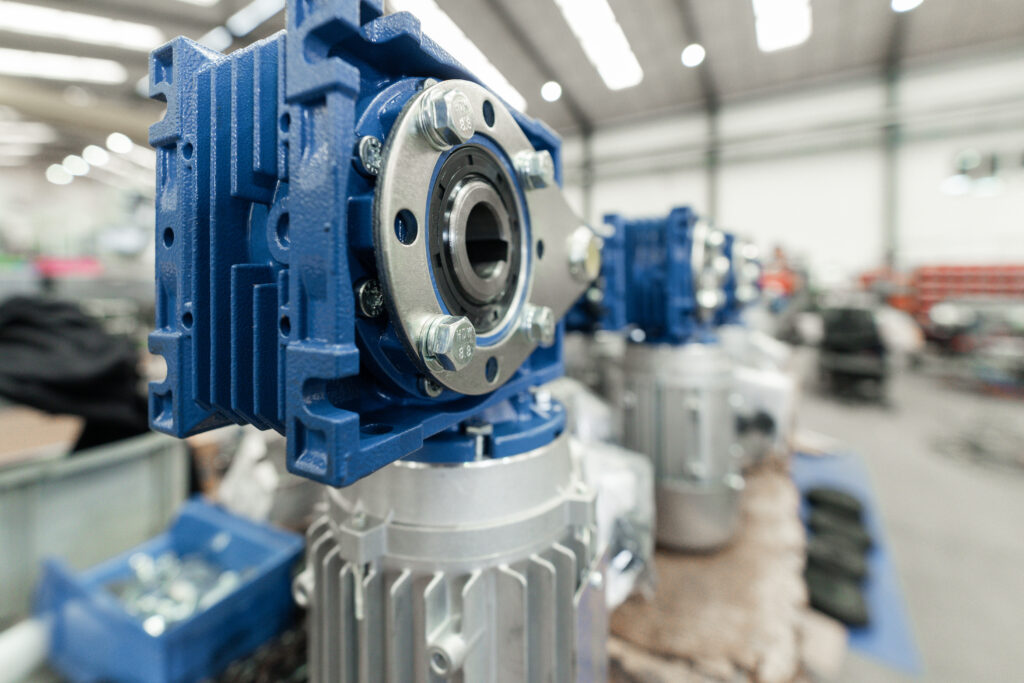

Research & Development

The MAF RODA Group devotes an average of 3% of its annual turnover to technological innovation.

This continuous investment in research has led to the MAF RODA Group holding numerous patents for different technological developments that enable it to offer its customers the most cutting-edge tools that best meet the requirements of their markets.

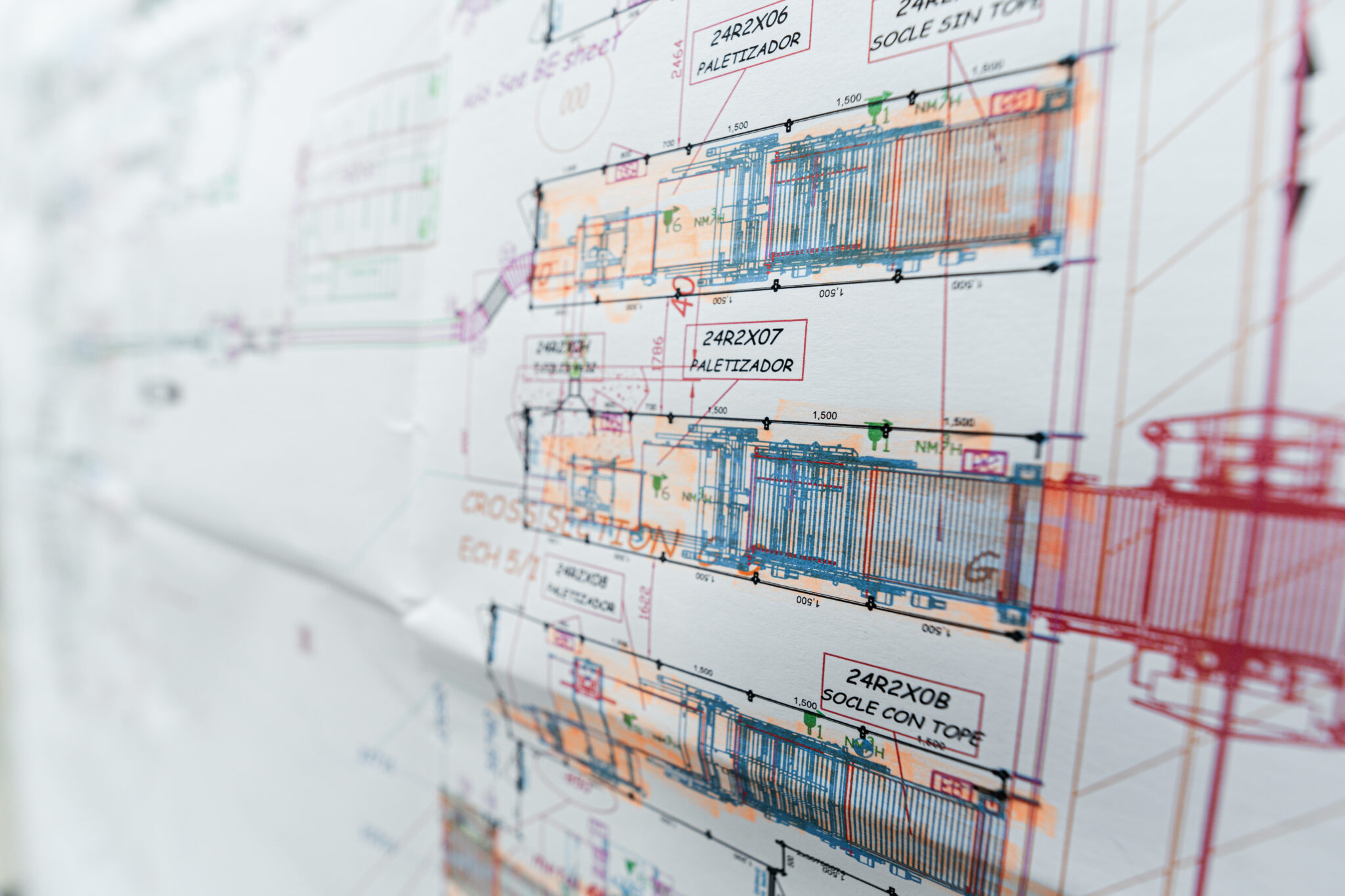

We have several research and development centres, the main ones being located at our sites in France, Spain and the United States. Each of them leads different projects, depending on the type of fruit or the nature of the project itself, such as electronic systems, software, robotics or automation.

Our 6 research areas

provide solutions tailored to the needs of our customers and we classify them as follows:

Mechanical Engineering

Traceability

Electronics

Automation

Electricity

Robotics

DISCOVER OURCustomers Testimonials

If you wish, you can learn about our success stories with clients by exploring how each one has been developed and the experiences gained. We invite you to discover the details of each collaboration, from the initial stages to implementation.