Zone

- Australia

- Chile

- France

- Italy

- Mexico

- New Zealand

- Peru

- South Africa

- Spain and Portugal

- United States and Canada

- Africa

- Asia

- Europe

- Latin America

Language

- French

- Spanish

- English

- Services

- About us

- Research & Development

- Careers

- Contact us

Tomato

It is time to take a step forward in electronic sorting, sizing and packaging technology for tomatoes with MAF RODA. Increase your productivity and reduce costs.

Trust the leader in postharvest solutions MAF RODA to cover all your tomato processing needs, from the moment the fruit is received in the warehouse until the moment it is packaged and palletized with the final strapping.

Our wide range of solutions are designed from the minute the fruit enters, to offer a homogeneous and constant dumping, through high-precision calibration and classification to unlimited packaging methods.

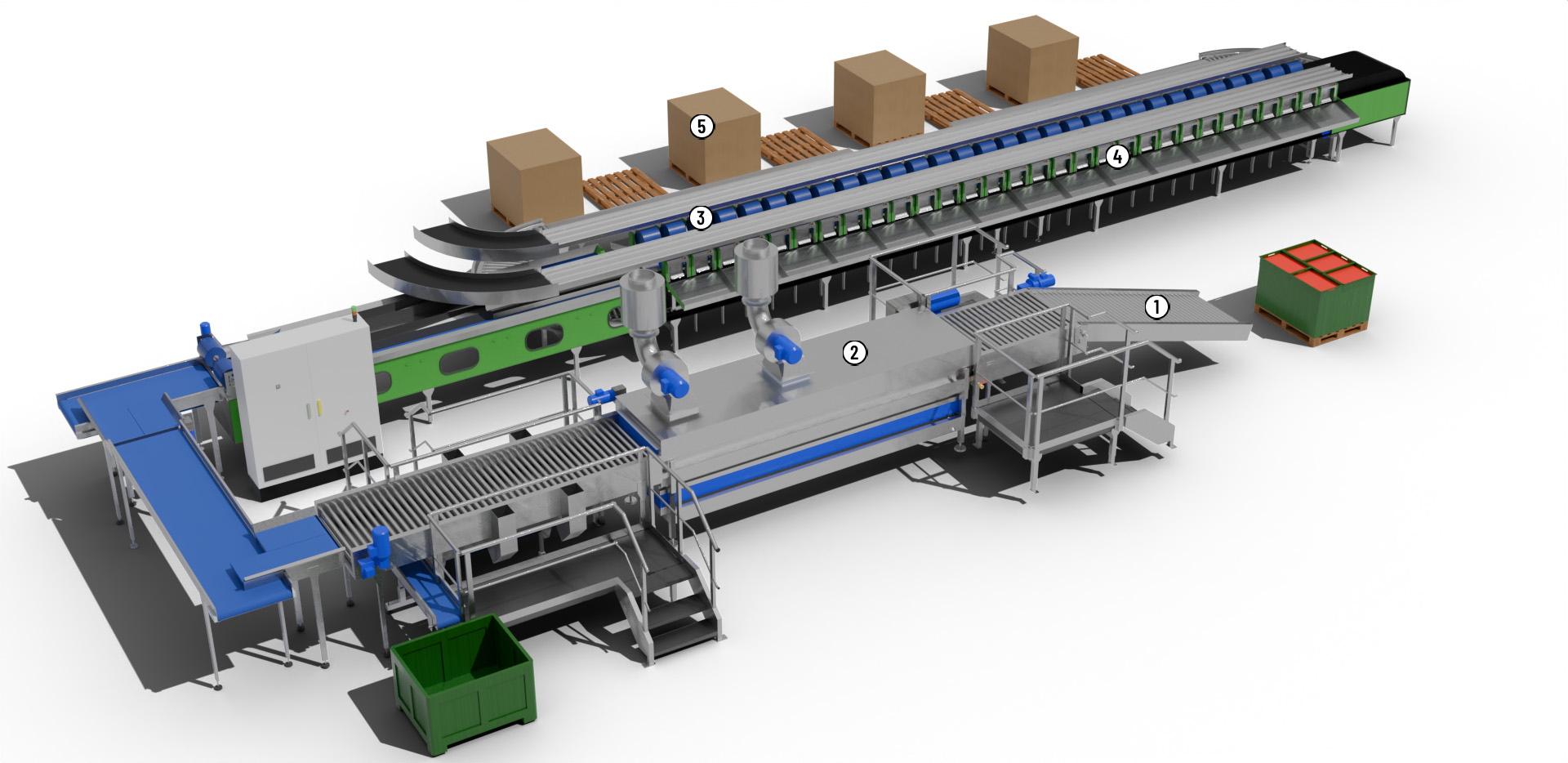

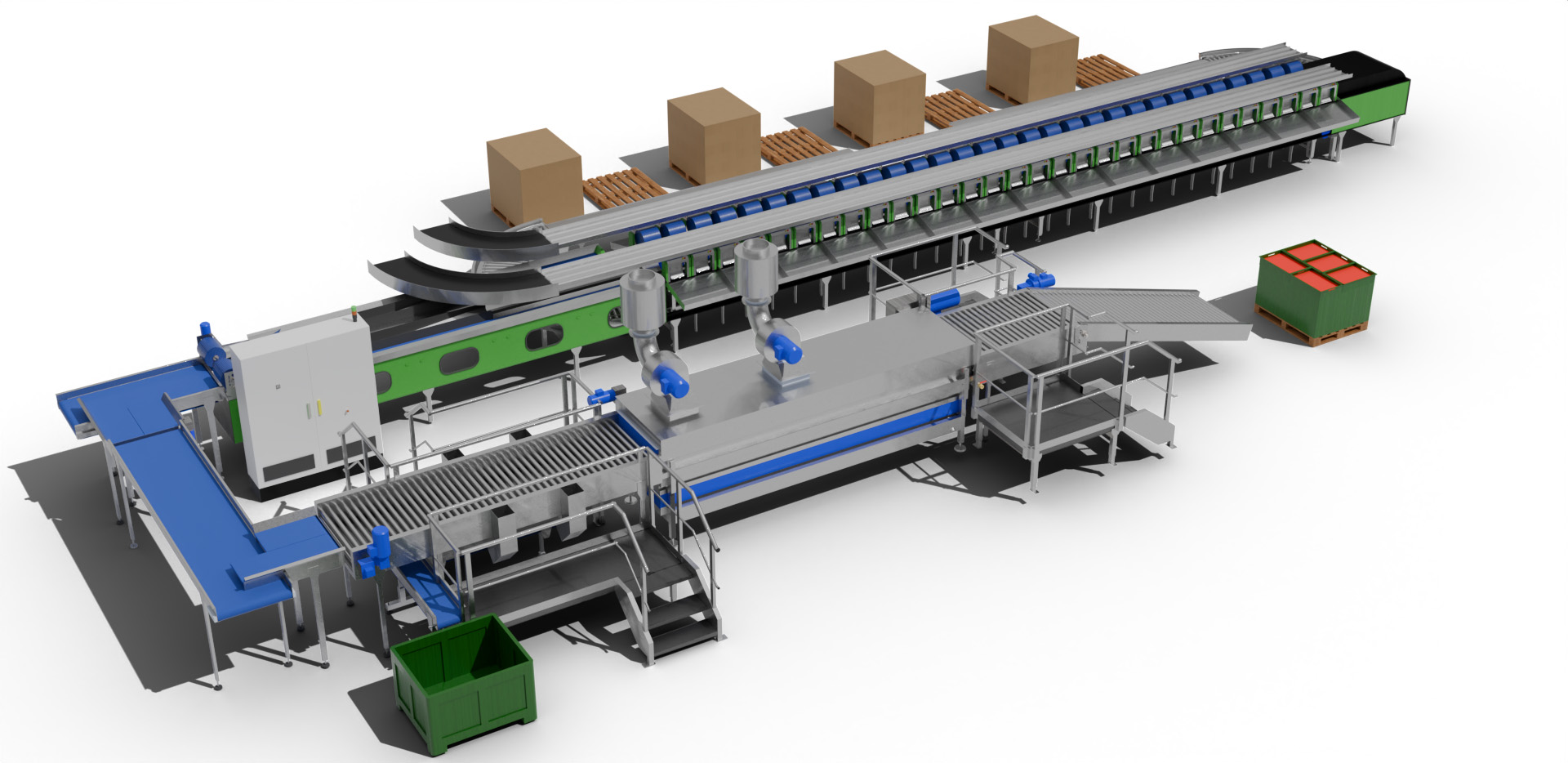

Our turnkey solutions for Tomato

Select the point on the line you want to cover to see all the available solutions. At MAF RODA we design turnkey projects, so if you need to speak to an agent, do not hesitate to fill out the contact form.

In this video, check out a tomato installation from one of our numerous customers and see first-hand the work we carry out with a high level of commitment and satisfaction of our customers.

POMONE IV

Once again, the POMONE IV calibration system is chosen by our customers as the most versatile and powerful on the market.

Due to its versatility in working with different varieties of fruits from large to medium, it is capable of offering a high degree of production with a complete rotation under cameras, a very precise modular weight system and a particularly delicate handling of the fruit and/or vegetable.

GLOBALSCAN 7 - UV

GLOBALSCAN 7 defines the degree of final excellence of your product.

Thanks to its cutting-edge technology with the use of Big Data and artificial vision, the system readjusts to the customer’s needs and perfects the detection of defects in the external analysis of fruit quality. With the UV version, the system can also detect fresh cuts on tomatoes.

A system that is committed to precision, efficiency and quality.

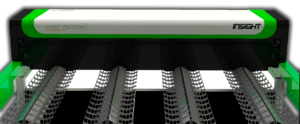

INSIGHT

Thanks to internal quality analysis systems, INSIGHT, characteristics such as dry matter can be known and thus ensure taste consistency of the final product.

It is also used to detect Brix levels (sugar content) and to assess the stage of ripeness (firmness) in tomatoes.

Our best sellers

Discover a wide selection of equipment and products designed for working with this fruit. Below, we showcase the most efficient machinery. Find the best options to enhance your facilities.

Discover ourCustomers Testimonials

Would you like to learn more about real installations for this type of fruit? Below, we share examples of satisfied clients who have trusted MAF RODA to enhance their production.